DynaSand Filtration - Hagerstown, MD

Overview

Located in northwestern Maryland with a population of 39,000, Hagerstown ranks as the state's sixth largest city. The city's wastewater treatment plant discharges into the Chesapeake Bay watershed and is regulated by the Maryland Department of the Environment (MDE).

Challenge

The Hagerstown Wastewater Treatment Plant (WWTP) was required to upgrade their Biological Nutrient Removal (BNR) process to meet the Enhanced Nutrient Removal (ENR) regulations established by the MDE. The ENR regulations reduce discharge limits from a BNR treatment level of 8 mg/l to 3 mg/l for total nitrogen and 2 mg/l to 0.3 mg/l for total phosphorous.

The MDE began formulating guidelines for implementation of an ENR policy for WWTPs discharging into the Chesapeake Bay in November 2002. These guidelines established goals to reduce nitrogen discharge from Maryland wastewater treatment plants by an additional 7.5 million pounds per year and phosphorus by an additional 282,000 pounds per year over BNR removal levels by the year 2010. The Bay Restoration Act, signed in 2004, provided funding for implementation of the required ENR upgrades for all major wastewater treatment plants throughout the state. The Bay Restoration Grant Program became available at the beginning of 2006.

Solution

After evaluating alternative treatment technologies for the Hagerstown WWTP ENR upgrade, the City’s engineer, Black & Veatch, determined that the DynaSand® upflow, deep bed denitrification filters offered a significant cost saving over other conventional filter technologies. However, since the DynaSand® filters had not previously been used to achieve such low nitrogen or phosphorus limits, a four month pilot testing program was undertaken to determine the combined nitrogen and phosphorus removal capabilities of the filters. The pilot testing results showed that the DynaSand® filters were capable of consistently maintaining effluent Nitrite/Nitrate Nitrogen (NOx-N) concentrations below 1 mg/L and effluent Total Phosphorus (TP) concentrations below 0.3 mg/L under a wide range of hydraulic loading and influent nitrate and phosphorus concentrations.

For the design and operation of the denitrification system, the addition of an external carbon source is required. Methanol dosage is controlled in response to continuously monitored NO2-N, NO3-N and dissolved oxygen concentrations and paced to filter influent flow to minimize chemical cost and prevent breakthrough of BOD in the plant effluent. Ferric chloride is also dosed immediately ahead of the filters when necessary to trim effluent TP concentration. The results of the DynaSand® filter performance showed no increase in effluent BOD. Also, the denitrification objectives were consistently met under sustained winter wastewater temperatures of 13 to 15o C (55 to 59o F).

Implementation

Based on the success of the pilot test, Hagerstown WWTP decided to build the DynaSand® filtration system to meet the ENR requirements. The maximum monthly average flow to be treated by the system is 15.9 MGD with an annual average flow of 9.9 MGD. Parkson provided the complete treatment system consisting of filters, analyzers, controls, instrumentation, and sample pumps. The filter’s design consists of seven cells with 10 modules per cell, for a total of 70 modules. Each module has 50 ft2 of filtration area which equates to 3,500 ft2 of total filtration area, and 80 inches of effective filtration media depth.

Lessons Learned

During high-flow events (up to 30 MGD) the plant has to blend primary and secondary effluent. These non-standard conditions flushed large clumps of algae from the final clarifiers, which clogged some of the filter sand air lifts and affected the operation of the filters. The plant is looking at options for covering the clarifier launders to eliminate the algae before the filtration and disinfection systems.

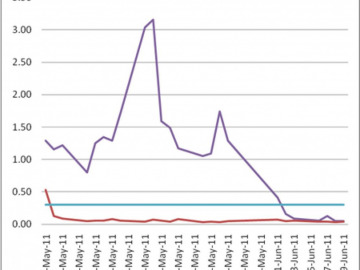

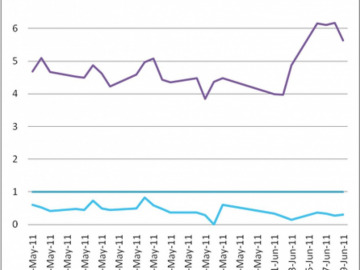

Results

After the installation and start-up of the system, the results from the pilot testing were reflected in the full scale project. The filters successfully met the specified performance tests, producing an average effluent NOx-N of 0.45 mg/l, better than the specified requirement of ≤1 mg/l. The reduction of total phosphate was also better than the specified requirement of <0.3 mg/l producing an average effluent of 0.15 mg/l.

There was no net increase of BOD and COD across the filters showing no evidence of methanol breakthrough, confirming that methanol was not overdosed. This validates the controls logic used by the DynaSand® ENR system. Another important control variable is the online instrumentation readings, which were comparable with the plant laboratory results and required no further calibration.