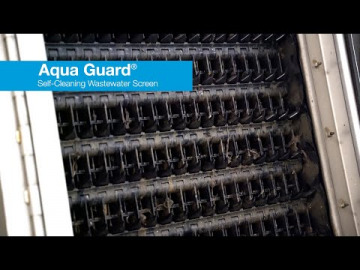

The Aqua Guard® is a rugged and proven self-cleaning, traveling water screen that uses a unique filter element system, which automatically removes a wide range of floating and suspended solids from a wastewater stream.

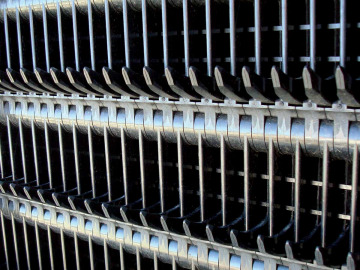

These unique elements are woven together on stainless steel shafts to form the endless moving belt that collects, conveys and ultimately discharges the solids that are being removed from the treated wastewater.

The Aqua Guard® is capable of performing in a wide range of applications and element spacing settings – from 1mm to 30mm –depending on the requirements of the specific treatment process.

Principle of Operation

Solids larger than the nominal screen opening contained in the wastewater stream are captured on the filter elements and conveyed upward on the face of the filter belt to be discharged at the rear of the unit. The traveling screen system uses a two-stage screening method that allows the screen to filter out solids much smaller than the screen opening. This is achieved through coarse filtration on the leading edge of the belt, while fine screening takes place on the recessed face resulting in minimal headloss.

The Aqua Guard® utilizes three principle-cleaning modes. The elements themselves are self-cleaning. As the tip of one row of elements passes between the shanks of the elements on the lower row, the elements are cleaned of collected solids. The traveling screen systems are also equipped with a rotating brush that provides positive removal of any additional solids that might remain on the belt. Finally, optional water sprays can provide a final polishing on the element belt in especially rigorous applications.

Design Options

The Aqua Guard® comes in standard screen widths from 1.0’ to 9.0’ depending on the model chosen with flow rates up to 100 MGD through a single unit. Two frame styles are available: Type A – The Pivoting Design and Type T – The Fixed Frame Design.

Why We Use Plastic Elements on a Headworks Screen

Looking for additional information? We're here to help.