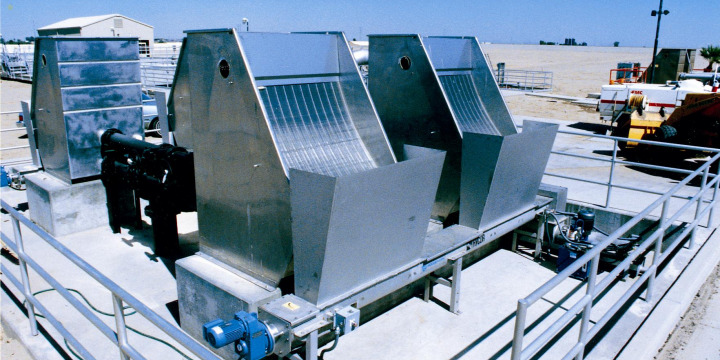

Hycor® Hydroscreen™ offers proven and reliable performance in liquid/solid separation for municipal and industrial applications, particularly for screening fibrous and non-greasy solids. There are no moving parts, motors, or complicated connections. The liquid/solid separation screen is economical and simple to operate.

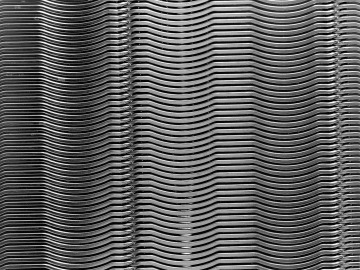

Features include customizable headbox, bi-wave screen panel, and drip lip, all of which make Hydroscreen superior to any other solid/liquid separation equipment in the industry. Building on Parkson’s experience with screens, Hydroscreen is manufactured to the highest standards. This proven static screen design has been used in more than 1,000 installations around the country.

In wastewater treatment plants, the Hydroscreen is renowned as a fine screen for pretreatment and/or use as grit dewatering equipment. Industrial users, such as meat processors, food processors, tanneries, textile mills, and recyclers, rely on it for product recovery and wastewater treatment. Pulp and paper mills use it for fiber recovery and rejects handling.

Opening sizes range from 0.010" to 0.100" (.25 to 2.5 mm), and hydraulic capacities range from 70 to over 2,700 GPM (16 to 620 m3/h). The standard build employs 304 stainless steel, while 316 and L grades are available as well. Heavy-duty models are available for heavy solids loadings.

Looking for additional information? We're here to help.